High-temperature fluorine-based grease, also known as perfluoropolyether (PFPE) grease, is a high-performance lubricant formulated from PFPE base oil and specific fluorinated thickeners. The molecular structure of PFPE is dominated by carbon-fluorine (C–F) bonds, which impart the grease with distinctive performance characteristics:

High-Temperature Resistance:

High-temperature fluorine-based grease remains stable under extreme temperature conditions. Its operating temperature range is broad, typically from -50°C to +250°C, and some high-end products can withstand temperatures above 300°C without oxidation, decomposition, or evaporation.

Chemical Inertness:

Due to the high electronegativity of fluorine atoms, PFPE exhibits excellent resistance to most chemicals, showing minimal reaction with acids, bases, organic solvents, or strong oxidizers. This effectively prevents degradation or failure of the grease when in contact with these media.

Low Volatility and Long Service Life:

High-temperature fluorine-based grease exhibits extremely low vapor pressure and minimal evaporation loss, allowing it to maintain effective lubrication even in vacuum environments. Its service life far exceeds that of conventional greases, providing long-lasting and stable lubrication throughout the entire equipment lifecycle.

Low Friction Coefficient and Excellent Lubricity:

This type of grease can significantly reduce friction between contact surfaces, minimizing wear and improving the operational efficiency and reliability of machinery. Additionally, it offers excellent shear stability and load-carrying capacity, making it suitable for high-load or high-speed precision components.

Electrical Insulation and Anti-Contamination:

High-temperature fluorine-based grease has excellent electrical insulation properties, meeting the lubrication and insulation requirements of electrical equipment. Moreover, it resists dust and particulate contamination, helping to maintain equipment cleanliness and reduce the risk of malfunctions.

In modern industrial systems, the application value of high-temperature fluorine-based grease is undeniable. It is widely used in aerospace, semiconductor manufacturing, precision instruments, new energy, chemical, medical equipment, and military industries, and plays a crucial role in the following key scenarios:

High-temperature operations: Lubrication of bearings, chains, valves, and seals in equipment such as metallurgy, glass manufacturing, ceramic sintering, heat treatment furnaces, and high-temperature ovens.

Extreme chemical environments: Equipment operating under aggressive chemical conditions, including chemical reactors, pharmaceutical equipment, and electroplating production lines.

High-vacuum environments: Applications requiring stable lubrication in semiconductor chip manufacturing, vacuum coating, and scientific research equipment.

Precision systems with strict lubrication requirements: Systems that demand cleanliness, durability, and precise lubrication, such as precision machine tools, optical instruments, aerospace components, and medical devices.

Founded 25 years ago, EUBO New Materials is a leading enterprise specializing in the research, development, and production of lubricants. Leveraging deep industry experience and continuous innovation, EUBO has a professional laboratory and R&D team, dedicated to providing customers with customized, high-performance fluorine-based high-temperature lubrication solutions. EUBO’s product line covers various high-temperature fluorine-based greases, strictly adhering to international standards while demonstrating the following advantages in practical applications:

Technological Leadership: Utilizing proprietary R&D capabilities, EUBO’s high-temperature fluorine-based greases are formulated with cutting-edge technology to ensure industry-leading performance in thermal stability, chemical inertness, and low volatility.

Reliable Quality: Each batch undergoes strict quality control, ensuring stable performance and meeting customer requirements for long-term reliable lubrication.

Customized Solutions: EUBO offers personalized product customization tailored to specific industry conditions, helping clients find the most suitable high-temperature fluorine-based grease for their equipment.

Technical Support: A professional technical team provides comprehensive consulting, application guidance, and troubleshooting support, ensuring efficient implementation and optimization of lubrication solutions.

Shenzhen EUBO is a national high-tech enterprise specializing in the R&D, production, and sales of new materials. Established in 2000, the company has a professional lubricant R&D team and an independent testing laboratory. Main products include: high-temperature greases, automotive greases, bearing greases, electronic lubricants, electronic adhesives, PUR hot melt adhesives, module frame adhesives, and more. For further information, please contact us directly.

With the advancement of modern industry, machinery is evolving toward high precision, high efficiency, ultra-large and ultra-small sizes, high speed, heavy load, energy saving, high reliability, and ease of maintenance. As a result, the operating temperatures of friction points in machinery are steadily increasing, placing greater demands on the high-temperature resistance and anti-wear performance of lubricating greases.

Most commonly used greases—such as calcium-based, sodium-based, and barium-based single-metal soap greases—tend to soften, bleed, or volatilize under high temperatures, losing their lubrication effectiveness. This often leads to equipment wear, increased noise, or even damage, adversely affecting normal production operations.

To address these challenges, EUBO has introduced its high-temperature grease, designed to provide reliable lubrication under extreme operating conditions.

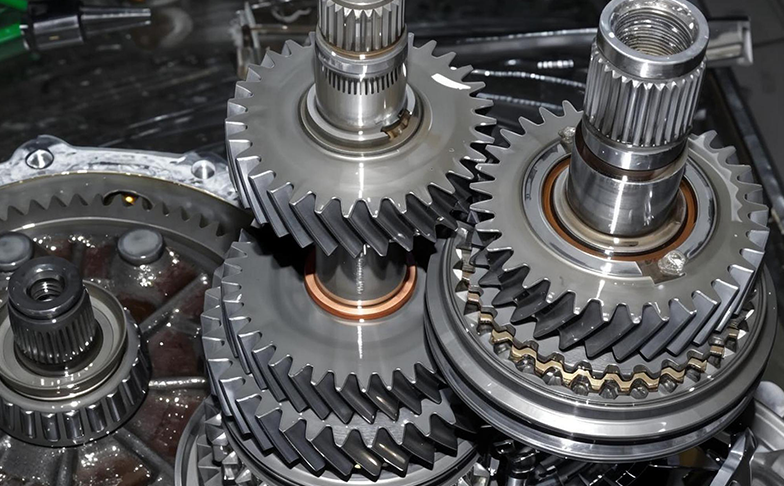

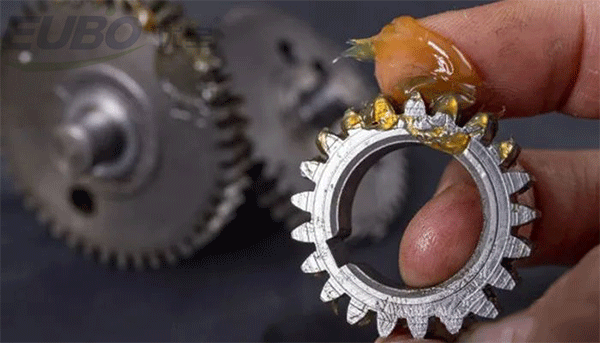

EUBO High-Temperature Grease is a high-viscosity perfluoropolyether (PFPE) grease thickened with polytetrafluoroethylene (PTFE) and refined with special anti-corrosion additives. This fluorine-based grease is specifically designed for bearings, gears, and components requiring lifetime lubrication under high-temperature, high-speed, heavy-load, and chemically aggressive environments. It offers excellent chemical inertness, durability, and low volatility, with an operating temperature range of -50°C to 250°C.

Wide Temperature Lubrication: Formulated with medium-viscosity modified silicone oil, it provides long-lasting and superior lubrication from -50°C to 250°C, effectively reducing wear and maintaining precise part alignment.

Strong High-Temperature Adhesion: Prevents grease from dripping under high heat, maintaining a continuous lubricating film.

Excellent Thermal Stability: Resistant to deterioration, it does not carbonize, coke, discolor, emit odors, or bleed, ensuring reliable long-term operation in high-temperature environments.

High Film Strength and Load Capacity: Offers a load-bearing capacity three times that of conventional greases. Lubrication is long-lasting, reducing the need for frequent replenishment and lowering maintenance costs.

Good Colloidal and Shear Stability: Exhibits very low oil separation, preventing contamination of other components. The consistency changes minimally after shearing.

Wide Compatibility: Compatible with most materials, including rubber, plastics, and metals, enabling broad application.

Chemical and Water Resistance: Insoluble in water and most solvents, and compatible with engineering plastics and elastomers. Stable against strong acids, strong bases, and halogens, making it suitable for lubrication and sealing in corrosive environments.

Lubrication and friction reduction for bearings, gears, guides, cams, and other components operating under extremely high temperatures and heavy loads where conventional greases cannot perform.

Especially suitable for lubrication of bearings in:

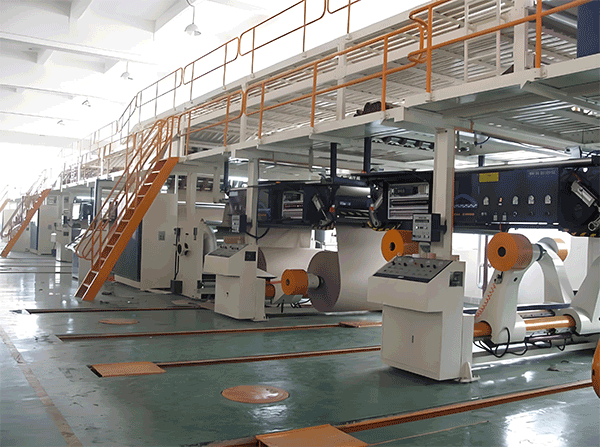

Film stretching machines

Heat-setting conveyor belts

Corrugated paper machines

Hot air blowers

Hot oil pumps

High-temperature motors

Fuser rollers in printers and copiers.

Lubrication of high-temperature valves and seals.

Applications requiring minimal lubricant volatility, such as cleanroom equipment and semiconductor manufacturing devices.

Other harsh environments, including low or high temperatures, corrosive media, solvents, and liquefied natural gas (LNG).

EUBO High-Temperature Grease provides comprehensive lubrication for high-temperature friction points, preventing bleeding, dripping, carbonization, and coking. Its excellent film strength and high load-carrying capacity significantly reduce friction and wear, ensuring smoother equipment operation and extending service life.

For more information on our grease products, please contact customer service or visit our website: www.chinaeubo.com

Dry film lubricants are coating materials in which solid lubricant particles are dispersed within a binder system. After application, they can cure at room temperature or under heat, forming a solid lubricating film with specific functional properties. These products combine the advantages of lubrication technology and surface engineering, making them an essential part of modern high-performance lubrication materials, and they are widely used across various industrial sectors.

To ensure that dry film lubricants deliver optimal performance, proper surface preparation and application procedures are crucial. The specific steps are as follows:

Before coating, it is essential to thoroughly remove oils, dust, and oxides from the substrate surface. Inadequate cleaning will directly affect the adhesion strength and service life of the coating.

The substrate should undergo chemical conversion (e.g., phosphating, passivation) or physical treatment (e.g., sandblasting, roughening) to significantly enhance the bonding between the film and substrate. This step is indispensable in the application process.

After surface pretreatment, any residues must be removed, and the substrate must be completely dry to prevent moisture or contaminants from compromising the coating quality.

Depending on the operating conditions and functional requirements of the components, an appropriate application method—brushing, spraying, or dipping—should be selected. The coating is then cured under the recommended conditions, forming a uniform and stable dry lubricating film.

Dry film lubricants are suitable for a wide range of materials, including metals, plastics, and rubber, and perform exceptionally well in situations where conventional lubricants are insufficient. They can be used in combination with conventional lubricants for synergistic effects or applied alone as a permanent or corrosion-resistant lubrication solution.

Their applications span office equipment, household appliances, automotive manufacturing, and general machinery, and extend to high-tech sectors such as aerospace. They are suitable for trial assembly, friction control, corrosion protection, and long-term lubrication requirements.

High-temperature environment: Under high-speed and heavy-load operating conditions, gear components often experience elevated temperatures, with local temperatures reaching 200–300°C. If the grease lacks sufficient high-temperature resistance, its base oil and thickener are prone to thermal oxidation, resulting in a decline in lubrication performance.

Influence of chemical contaminants: Prolonged exposure of grease to air, or contact with industrial gases containing sulfur, nitrogen oxides, and other contaminants, can accelerate the oxidation process, leading to structural degradation and an increase in acid value.

Exposure to humid environments or direct contact with water can disrupt the structure of the grease, triggering emulsification, hydrolysis, and other reactions, which in turn accelerate oxidation and degradation.

Metal wear particles (such as iron or copper) generated during gear operation can act as catalysts, significantly increasing the oxidation rate of the grease.

Choose grease products with excellent antioxidant properties and thermal stability, especially under high-temperature and heavy-load conditions. Pay attention to their oxidation induction period and corrosion resistance.

Maintain proper sealing of the gear system to prevent ingress of water, dust, and other contaminants. Regularly clean the equipment and inspect the condition of lubricated parts.

By improving heat dissipation conditions or adding cooling devices, the gear system temperature can be maintained within a reasonable range, helping to extend the service life of the grease.

Develop a grease replacement cycle based on equipment usage, and monitor the grease oxidation status through oil analysis techniques to implement preventive maintenance.

Proper grease selection is key to ensuring the long-term stable operation of gears. It is recommended not to choose ordinary grease based solely on price, but to focus on technical compatibility and product reliability. Prioritize suppliers with comprehensive R&D capabilities and proper certifications to ensure optimal lubrication performance and equipment longevity.

Shenzhen Eubo has been dedicated to the lubricant materials field for 23 years, focusing on the research and production of bearing greases, high-temperature greases, and other specialty lubricants, with extensive technical expertise and practical experience. We welcome inquiries and cooperation from customers with relevant needs.

The smooth and controlled opening and closing of a toilet seat is attributed to the sophisticated design between the damping shaft and the shaft sleeve. When the seat is lifted, motion is transmitted through the bearing, allowing the shaft and sleeve to rotate together. During this phase, the damping mechanism remains inactive, ensuring the cover can be raised effortlessly.

When the seat begins to descend, the intricate directional locking mechanism engages, causing the shaft and sleeve to disengage and the shaft to form a reverse lock with the sleeve base. Through the combined action of the damping mechanism and the damping grease, the toilet seat closes slowly and uniformly, achieving a smooth and steady descent.

Damping Grease

Damping grease is a specialty lubricant formulated from high-viscosity synthetic oil, specifically designed for mechanisms requiring cushioning, such as toilet seat hinges. It operates reliably over a wide temperature range of -30°C to 150°C and is safe, non-toxic, non-corrosive, and low in volatility.

More importantly, it provides excellent anti-wear lubrication and outstanding damping performance, effectively slowing the descent of the toilet seat during closure. This prevents harsh collisions between the seat and the toilet bowl, eliminates noise, reduces potential damage, and enhances the overall user experience. It also finds broader applications in other mechanisms requiring controlled cushioning.

In addition to its use in toilet seat slow-close systems, damping grease is also widely applicable to various mechanisms requiring cushioning and noise reduction, such as door and window hinges, furniture hinges, and rotating shafts. Whether applied to metal or plastic hinges, it provides long-lasting protection and ensures smooth operation, significantly enhancing the durability of the product and the overall user experience.

Damping grease is a functional grease made from specially selected polymers, specialty additives, and thickeners through a unique manufacturing process. It features excellent adhesion, high viscosity, superior lubrication performance, chemical stability, and mechanical stability. It is particularly suitable for positions between plastics and metals that require long-term damping (buffering, resistance) and lubrication.

Typical application areas of damping grease include:

Sealing and leak-prevention parts: Such as sealing valves in water or fuel gates, used for lubrication and leak-proof filling.

Precision instruments: Parts that require damping and buffering.

Household products: Items that need cushioning or a naturally comfortable tactile feel.

Hardware and power tools: High-end door hinges, faucets, power tools, and movable joints in plastic toys.

Office equipment and mechanical structures: Internal plastic or metal moving parts in office equipment, toys, gearboxes, etc., requiring lubrication, noise reduction, shock absorption, or resistance functions.

Special application case: High-end door hinges.

Over the past two decades, high-end door hinges—typically made of premium stainless steel or brass—have widely adopted fully synthetic damping grease, originally used for protecting optical and automotive components, as their core lubrication material. The grease is injected into the hinge pivot before leaving the factory, offering significant advantages:

Excellent adhesion: Minimizes grease loss.

Superior lubrication and corrosion protection: Extends the service life of the hinge.

Long-lasting noise reduction and damping: Ensures smooth, quiet opening and closing with an appropriate resistance for tactile feedback.

Important note: Temperature effect on viscosity

The viscosity of damping grease varies with temperature: it decreases at high temperatures and increases at low temperatures. Therefore, when selecting damping grease:

Always choose viscosity according to the actual operating temperature range.

For high-temperature environments requiring stable viscosity, select products with excellent high-temperature performance and a high viscosity index.