1. Main Causes of Oxidation in Gear Grease

High-temperature environment: Under high-speed and heavy-load operating conditions, gear components often experience elevated temperatures, with local temperatures reaching 200–300°C. If the grease lacks sufficient high-temperature resistance, its base oil and thickener are prone to thermal oxidation, resulting in a decline in lubrication performance.

Influence of chemical contaminants: Prolonged exposure of grease to air, or contact with industrial gases containing sulfur, nitrogen oxides, and other contaminants, can accelerate the oxidation process, leading to structural degradation and an increase in acid value.

Moisture and Contaminant Ingress:

Exposure to humid environments or direct contact with water can disrupt the structure of the grease, triggering emulsification, hydrolysis, and other reactions, which in turn accelerate oxidation and degradation.

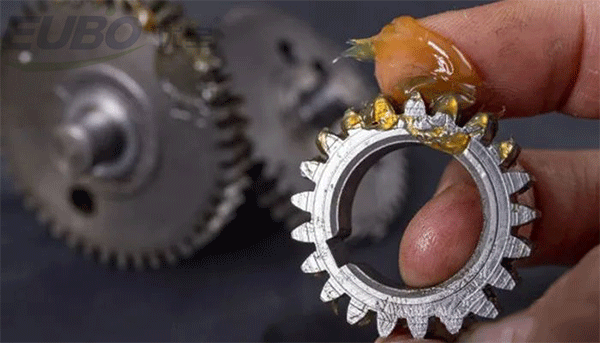

Metal Catalysis:

Metal wear particles (such as iron or copper) generated during gear operation can act as catalysts, significantly increasing the oxidation rate of the grease.

II. Effective Methods to Slow Down Grease Oxidation

Select High-Performance Grease:

Choose grease products with excellent antioxidant properties and thermal stability, especially under high-temperature and heavy-load conditions. Pay attention to their oxidation induction period and corrosion resistance.

Enhance Operating Environment Management:

Maintain proper sealing of the gear system to prevent ingress of water, dust, and other contaminants. Regularly clean the equipment and inspect the condition of lubricated parts.

Control Operating Temperature:

By improving heat dissipation conditions or adding cooling devices, the gear system temperature can be maintained within a reasonable range, helping to extend the service life of the grease.

Establish Regular Monitoring and Grease Replacement Schedule:

Develop a grease replacement cycle based on equipment usage, and monitor the grease oxidation status through oil analysis techniques to implement preventive maintenance.

III. Grease Selection and Management Recommendations

Proper grease selection is key to ensuring the long-term stable operation of gears. It is recommended not to choose ordinary grease based solely on price, but to focus on technical compatibility and product reliability. Prioritize suppliers with comprehensive R&D capabilities and proper certifications to ensure optimal lubrication performance and equipment longevity.

Shenzhen Eubo has been dedicated to the lubricant materials field for 23 years, focusing on the research and production of bearing greases, high-temperature greases, and other specialty lubricants, with extensive technical expertise and practical experience. We welcome inquiries and cooperation from customers with relevant needs.